Collaborative development across continents

The offices of MyLiveZone AG in Ipsach, Bern, are filled with rows of cabinets lined up side by side. If you look behind the glass doors, you will see square boxes of differing sizes, with interconnecting coloured cables and small blinking lights.

What you have in front of you is a training centre for various industrial companies. Instead of bringing programmers and technicians together in a room, sitting them down in front of the assembled products and explaining to them how they are used, companies do their product training and product presentations for their technical equipment right from here – completely digitally. “Our customers from industry have the product located on their premises somewhere. The person who works with it is stationed somewhere else. What our technology does it allow them to bridge the distance in between,” says Thomas Zürcher, founder and CEO of MyLiveZone AG.

"We have proven with our project that decentralised companies can speed up the development process for products with hardware and software parts, helping them get their products to market faster.”

Thomas Zürcher

Founder and CEO of MyLiveZone AG

Even the most complex systems can be accessed from anywhere within a matter of seconds via the remote centre in Ipsach. “Our customers only have to set up a room once and can then use it worldwide. MyLiveZone’s clientele includes large technology firms as well as medical technology companies: people who operate X-ray machines used to have to travel halfway around the world to learn in person on an expensive training device – but not anymore.

As if you were sitting right next to the product

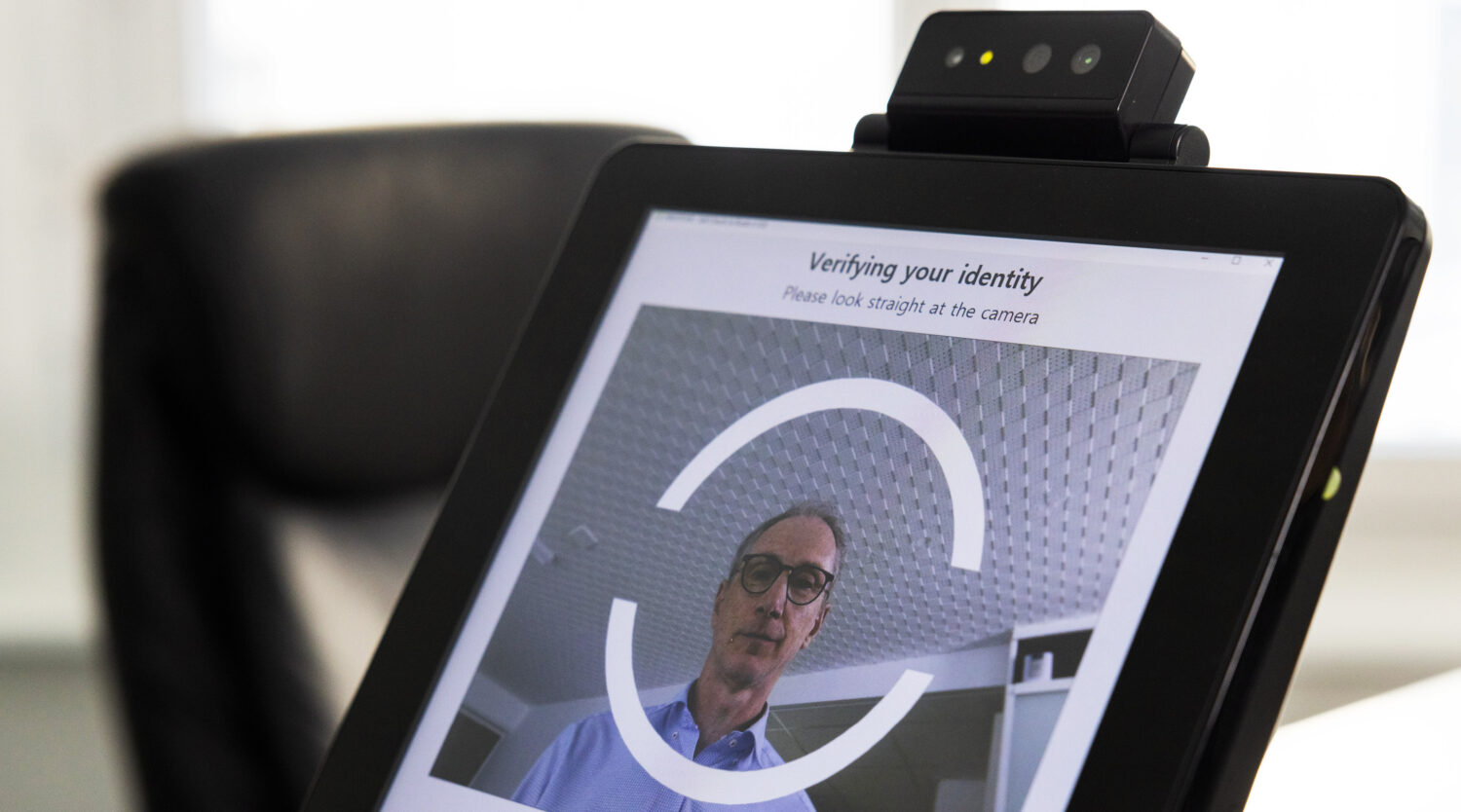

The products and their surroundings can be viewed in real time via a livestream. “Each person also has the option of using the computer to operate the product themselves. They can program, present or watch live what the machine is doing. This means they have the same possibilities available to them as if they were sitting right next to the product at the table.”

MyLiveZone emerged from the Bern University of Applied Sciences in 2010. At that time, the concept of remote training was difficult to explain, says Thomas Zürcher. In the meantime, a large number of industrial companies now have to engage with the topic of automation and robotics. “As industrial production becomes increasingly digitised, machines and products need to be equipped with more and more electronic components and system parts. And users need to be trained in them.”

Collaborating on development regardless of location or timezone

As part of an international Innosuisse project completed at the end of 2022, the Bern-based SME has demonstrated that its technology can be used not only to provide live online training, but also to develop a product jointly across continents. In the project, which was approved within the scope of a joint call for proposals by Innosuisse and the Brazilian agency EMBRAPII 2020, specialists from Switzerland and Brazil were able to work together across continents to develop software components, test them and successfully integrate them into a hardware prototype.

On the Swiss side, MyLiveZone was joined by the research partner Switzerland Innovation Park Biel and the software specialist cencerus AG, headquartered in the municipality of Schattdorf in Uri. Together with Brazilian implementation partner Altus AG, a manufacturer of automation components for industry, they proved that collaborative engineering between timezones is possible and efficient. And that expertise can be shared easily across continents. “The professionals in Switzerland have 'virtually' merged with the professionals at the Altus head office in Brazil."

During development of a product, the hardware and software teams need to be in consistent alignment, says Thomas Zürcher. “The two development teams are in constant contact, making adjustments, testing, giving feedback, etc. It’s an iterative process.” Software developers are dependent on performing certain tasks directly on the hardware, he says. The hardware solution was set up at Altus’ head office in Brazil. Instead of the product being sent back and forth between countries, MyLiveZone’s innovative technology means that the two teams are now able to work together completely online.

The development teams in Brazil and Switzerland were in contact with each other via video meeting, held in the afternoon Swiss time, to discuss details and plan next steps. During the rest of the day, they were able to work independently on the same product. “Cooperation with the Brazilian partner was very smooth and rewarding."

A win-win for all

"We have proven with our project that decentralised companies can speed up the development process for products with hardware and software components, helping them get their products to market faster,” says the MyLiveZone CEO. “Once the product is ready for production, they already have an online workplace where professionals can be trained in virtual classrooms around the world (see below).

Collaborative engineering is especially important for companies in times of delivery difficulties – and it is also more sustainable, emphasises Thomas Zürcher. “It requires fewer resources when you can use one product for multiple locations and don't have to send products back and forth. There's also no need for costly personnel logistics."

"For a company from an emerging economy like Brazil, cooperation with Switzerland is a boon. The country has a talented pool of skilled workers thanks to its excellent universities, not to mention economic and political stability."

Expanding the field of business

The project also marked a milestone for MyLiveZone. “It was important for us to show that our technology can be used to develop products across continents. This opens new doors and provides a new focus for our work going forward. It gives us the opportunity to be involved on a service level earlier on during the development of products and offer support where needed. So far, the focus has been on training for new products (see below).

"We were able to acquire a new business field and gained an attractive customer in Altus. The project has been very rewarding for us – it helps us build global confidence in our services."

The intercontinental cooperation on the project ultimately also ensures that it is based in Switzerland: the South American Altus Group plans to open its first office in Europe in the near future at the Swiss Innovation Park in Biel, and to develop some of its products out of Switzerland in future – in a collaborative effort with the hardware team in Brazil.

"Collaboration with research partners is very rewarding for us in the process of developing our technology. I am very grateful to Innosuisse."

Thomas Zürcher

Founder and CEO of MyLiveZone AG

An online agent helps combat the shortage of specialists

MyLiveZone’s remote centre in Ipsach also provides a platform for digital classroom instruction. Twelve people can dial in to the remote centre simultaneously – whether they are in the same room or located all over the world. Twelve virtual workstations are already there, waiting for them.

Before, instructors used to have to create learning documents/instructions for the course participants by hand. During training, they spent much of the time going from training workstation to training workstation, showing each person where they had to click next on their screen.

As part of an Innosuisse project completed in 2021, MyLiveZone developed an agent together with the Switzerland Innovation Park Biel. Before the course, the instructor goes through the product's software program one time with the digital assistant , showing them where to click. The training materials are created automatically while clicking. The instructor also has the option to add their thoughts on individual steps.

A completely new way of teaching for trainers and trainees

The course participants can click through at their own speed afterwards: they can see on their screen where they have to click or what they have to drag and where – including an explanation of what the individual step does or triggers. This way, everyone can learn at their own pace, and no one is left behind. “It’s a whole new way of learning.”

This works for all screen setups and sizes: the agent uses image recognition to locate where the next icon is that needs to be clicked – because the interface is arranged differently on each screen. That is something the instructor would otherwise have to do for each person individually, tying up valuable resources.

Follow-up project: Certifying professionals supported by artificial intelligence

The second innovation project, completed in spring 2023, builds on the findings from the first project. In the opposite direction, the agent can now follow what the trainee is doing during the course and compare this with the solution paths recorded in advance. “These recordings allow the instructor to stand virtually behind the users and review a particular sequence in more detail if needed.”

This gives the experts an insight into how students arrive at their solution or use the software. However, it is not just about judging what is "right" or "wrong"; perhaps the student choses a more efficient path than the instructor, or a certain sequence was especially ingenious even though it led to the wrong result.

Fairer evaluation of exams

Being able to assess the path to the solution means that exams are evaluated more fairly, says Thomas Zürcher. “I taught programming myself for over 20 years, and wasn't always able to evaluate fairly. As an instructor, you can’t examine every single line when someone is programming for three hours straight. Now the expert can see the step where something is still missing. That’s important feedback for learners.”

As the agent is developed further, in future it will be possible to certify skilled workers – something that is extremely important in the industry – directly during practical learning. This is a particular advantage at a time when companies are facing a shortage of skilled workers.

Support from Innosuisse

- 1 international innovation project with Brazil

- 2 Swiss innovation projects

- Mentoring

- Innovation cheque